The contact print and labelling system in a robust industrial design with integrated thermal direct and thermal transfer printing module is suitable for the labelling of a wide range of products, which depend on product-specific and variable labelling. By printing and applying the labels in one step, the greatest possible flexibility is guaranteed.

System types

- P 104 – max. label width 116 mm

- P 152 – max. label width 174 mm

System description

- Thermal direct & thermal transfer printing process

- 200dpi, 300dpi or 600dpi versions available

- Printing velocity from 100mm/s to 300mm/s

- Printing width from 104mm up to 168mm (depending on version)

- Label widths from 10 to 116mm or 50 to 174mm

- Carrier band widths from 25 to 120mm or 50 to 178mm

- Non-contact label scanning by light barrier

- Easy operation and low retooling times

- Extremely compact and robust construction

- Suitable for the processing of all common label materials and label formats

- Optimal integration capability in conveyor technology provided by the customer

- Interfaces: RS232 C 1200 to 230400 Baud – 8 Bit/USB 2.0 High Speed Slave for PC connection/Ethernet 10–100 Base T, LPD, RawIP Printing, DHCP, HTTP, FTP, SMTP, SNMP, TIME, Zeroconf, mDNS, SOAP/2× USB master for external control panel, keyboard, scanner, service key, USB stick/digital I/O interface (cab or OEM version)/Wireless Bridge 802.11b (optional)

- Optional left- and right-hand version

Available application variants

- Dispensing reed method – direct dispensing by means of dispensing reed methods (VarioTouch)

- Proof method – label is pressed onto the product surface using a vacuum plate and lifting cylinder (Airtouch)

- Blow on method – Label is blown onto the product surface by using a vacuum plate (Airkiss)

System accessories

- Product photo sensor including mounting material

- Incremental encoder with rubber-lined friction wheel

- Spool scanning for advance warning of end of label

- Mounting set for height adjustment

- Mounting set for vertical and lateral adjustment

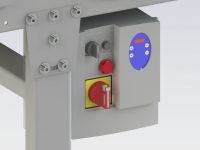

Conveyor belts

contact conveyor belt 1.2m

- Stainless steel and aluminium models

- Height-adjustable base frame

- Conveyor belt width 200mm or 350mm

- Conveyor belt length 1.2m

- Continuously adjustable from 3m/min to 30m/min

- Ball bearing mounted drive rollers

- Left- and right-hand version available

contact conveyor belt 2.0 m

- Stainless steel and aluminium models

- Height-adjustable base frame

- Conveyor belt width 220mm or 350mm

- Conveyor belt length 2.0m

- Continuously adjustable from 3m/min to 30m/min

- Ball bearing mounted drive rollers

- Left- and right-hand version available

contact conveyor belt divided 2.0 m

- Stainless steel and aluminium models

- Divided conveyor belt for bottom labelling

- Height-adjustable base frame

- Conveyor belt width 220mm or 350mm

- Conveyor belt length 2.0m

- Continuously adjustable from 3m/min to 30m/min

- Ball bearing mounted drive rollers

- Left- and right-hand version available